Contents:

In order to avoid unwanted multitasking during production, so-called Work in Process limits have been introduced. For example, in automotive companies such a limit may be the number of cars that enter the production line. If realistically only two cars can leave it, there is no point in letting 10 units onto it. Importantly, there should be one task for each person or each stage of the project – only after that task is completed, can the next activities proceed. In practice, however, this is often not the case, which translates into a significant decrease in the productivity of the entire organization.

Kenney administration is working to shorten wait times for project approval by zoning board – The Philadelphia Inquirer

Kenney administration is working to shorten wait times for project approval by zoning board.

Posted: Thu, 13 Apr 2023 20:24:13 GMT [source]

While work in process and finished goods refer to various stages in an inventory’s life cycle, they have clear distinctions. The tools and resources you need to take your business to the next level. The tools and resources you need to get your new business idea off the ground. Multimedia Hub Listen to the Mind the Business podcast by QuickBooks and iHeart. Self-Employed The tools and resources you need to run your own business with confidence. Midsize Businesses The tools and resources you need to manage your mid-sized business.

How to Supervise a Manufacturing Process

There’s a work-in-process methodology and a work-in-progress methodology . NetSuite supports production processes with a long lead time and can track item assemblies as a work in process. Most non-accountants think of work-in-process as a description of the physical state of inventory in a manufacturing operation.

Recently, an inventory glut has forced even large retailers to offer deep discounts and offload excess inventory, ultimately damaging earnings. In fact, CNBC reports that excess inventory levels will be the most important factor investors watch in upcoming quarterly earnings reports. Work in progress and work in process are variants of a noun phrase that means a job or project that isn’t finished yet. It might be helpful to think of progress as gradual change for the better, while a process is a sequence of discrete steps toward a predetermined goal.

How to Calculate Goods in Process Inventory

But in order to build the optimal inventory management system, you need the right tools. A high WIP inventory number can indicate that your production process isn’t flowing smoothly and that there may be bottlenecks in the process. By tracking WIP, you can pinpoint and eliminate these problems before they hurt your bottom line. The more WIP you have on hand, the more capital you have tied up in items waiting to be sold. Whereas, Work in progress takes a long time to convert into a finished product.

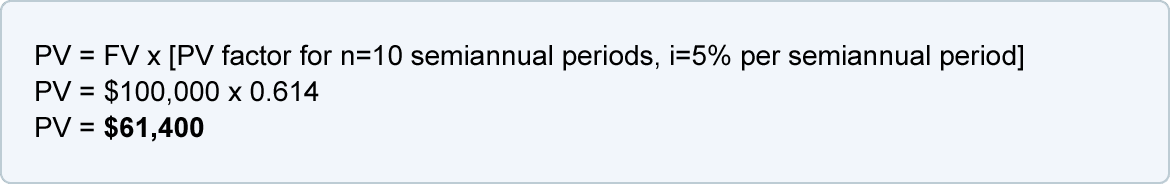

You will then add manufacturing costs for goods currently in production, and subtract the Cost of Goods Manufactured which have been moved to finished goods. COGM includes direct materials, direct labor, and manufacturing overhead. However, costs are incurred throughout the period and must be accounted for.

The amount of Work-in-Process Inventory would be reported along with Raw Materials Inventory and Finished Goods Inventory on the manufacturer’s balance sheet as a current asset. WIP inventory is usually calculated periodically or at the end of the financial year for accounting purposes. While this ensures balanced books, it doesn’t go a long way toward actual control over the WIP inventory throughout the manufacturing process. The beginning work-in-process inventory represents the value of all unfinished goods at the beginning of the new accounting period. In other words, it is the WIP asset section of the balance sheet of the previous accounting period. Work in process is usually measured at the end of an accounting period to most accurately value how many incomplete goods are still sitting within the production process.

Work in Progress Inventory vs. Work in Process

WIP stands for “work in progress” and refers to any partially complete inventory not yet ready to be sold to customers. If there are delays in the production process, having some WIP can help to keep things on track. For example, if the painting department is behind schedule, the frames that are already painted can be moved to the assembly line so that they’re not sitting idle. The work in process inventory formula is the Beginning WIP Inventory + Manufacturing Costs – COGM. Keeping tabs on your work in process inventory requires some bookkeeping. If you’re not an accountant, you may wonder how a work in process inventory journal entry looks.

It includes all the direct materials used, direct labor incurred, and manufacturing overhead applied to the unfinished product. Work in the process represents partially completed goods, or in other terms, these goods refer to be goods – in process. For a short period, work in the process is also considered a product moving to the finished product from raw materials. When combs are manufactured, plastic is moved into production as a raw material. Since the combs are only partially completed, all costs are posted to WIP.

WIP can provide a cushion if there are delays

Ideally, a lean straight line depreciation environment should contain so little work-in-process inventory that the amount on hand is immaterial. Work in progress is an asset account used to report larger undertakings. Work in progress projects usually span many accounting periods, have more complex and technical requirements, and represent larger jobs such as building a building. Work in progress items will have substantially less liquidity, and the company incurring work in progress costs may find it much more difficult to liquidate the asset as it is being completed. Work in progress items (i.e. the construction of a new warehouse or specialized piece of equipment) may be very specific to a company and hold little to no value to other market participants. Work in progress items may require substantial pricing discounts to entice buyers, especially if the items are not standardized.

See the renovation prep work at Old Greenwich School happening … – Greenwich Time

See the renovation prep work at Old Greenwich School happening ….

Posted: Wed, 12 Apr 2023 09:04:19 GMT [source]

For tax purposes, it’s best to track WIP inventory to get an accurate breakdown of what your inventory is actually worth. Control accounts are accounts in the general ledger that reports multiple subsidiary ledger accounts. Subsidiary ledger accounts provide details for the general ledger control account. Job order cost sheets are used to track manufacturing costs for each job if a job order costing system is used.

Adam Hayes, Ph.D., CFA, is a financial writer with 15+ years Wall Street experience as a derivatives trader. Besides his extensive derivative trading expertise, Adam is an expert in economics and behavioral finance. Adam received his master’s in economics from The New School for Social Research and his Ph.D. from the University of Wisconsin-Madison in sociology. He is a CFA charterholder as well as holding FINRA Series 7, 55 & 63 licenses. He currently researches and teaches economic sociology and the social studies of finance at the Hebrew University in Jerusalem.

The purpose of https://1investing.in/ is to determine the production cost at each process stage. This excludes the value of raw materials held up in inventory for sale and finished goods inventory held for the anticipation of future sales. In general, Work-In-Process inventory refers to partially completed goods that move from raw materials to a finished product within a short time frame. WIP inventory constitutes all materials that work has started on that are not yet finished in manufacturing operations.

- The two other categories of inventory are raw materials and finished goods .

- Either way, determining the value of work in progress can be time consuming, so companies try to minimize the WIP directly before the end of the accounting period.

- This means that you ended the year with no WIP inventory, which is ideal.

- Work in process inventory is a term for unfinished products waiting to be completed.

It goes without saying that all of a company’s financials need to be in shipshape also when applying for longer-term loans. Work in process, sometimes called work in progress or goods in process, refers to the production cost of partially completed goods. Most ecommerce businesses rely on a supplier or manufacturer for sellable inventory. The process and flow of WIP inventory are important to understand because they can indicate how efficient your supplier or manufacturer is at producing finished goods. By working closely with your supplier and other partners in your retail supply chain, like a 3PL company, you can find ways to optimize the supply chain.

- Finance Strategists is a leading financial literacy non-profit organization priding itself on providing accurate and reliable financial information to millions of readers each year.

- Any product that’s at this point of the manufacturing process is factored in here.

- If realistically only two cars can leave it, there is no point in letting 10 units onto it.

Work in process is used to report inventory items that are currently being constructed but are not yet done. Work in progress, on the other hand, is usually used to report capital assets on longer schedules that are not yet completed. Work in process items usually transfer to inventory, then are used to determine cost of goods sold. Work in progress is usually reported as a capital asset and depreciated when completed. Work in progress describes the costs of unfinished goods that remain in the manufacturing process, while work in process refers to materials that are turned into goods within a short period. The terms work in progress and work in process are used interchangeably to refer to products midway through the manufacturing or assembly process.